Project Overview

Industrial Engineering Senior Capstone Project in collaboration with Orest Volchanin (IE, ’23) and Chloe Wegener (IE, ’23)

This capstone project focused on improving the ergonomics and productivity of Android Industries’ rear axle assembly line. Operators were facing significant physical strain due to repetitive movements and outdated equipment, which not only impacted safety and operational efficiency but also led to increased fatigue and potential health issues.

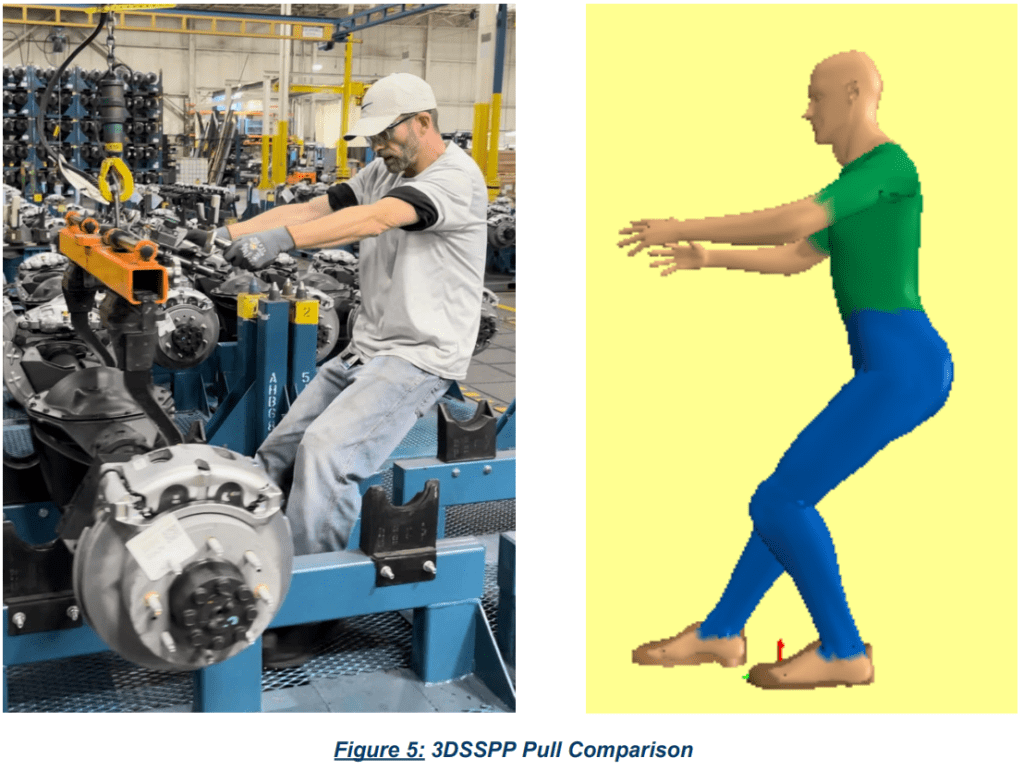

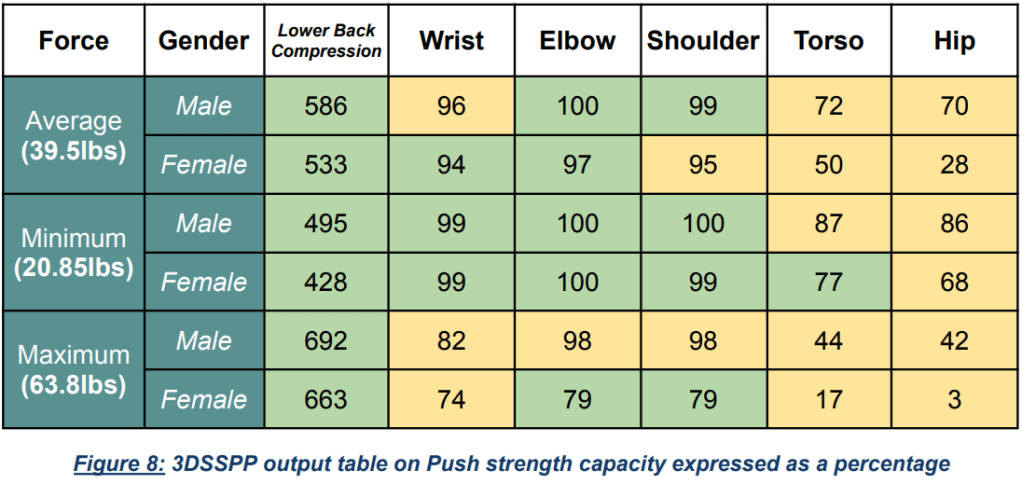

Recognizing these challenges, the project team undertook a comprehensive assessment of the assembly line’s processes. By utilizing advanced ergonomic tools such as the ART Tool and 3DSSPP, they meticulously analyzed each aspect of the assembly line, identifying key areas where improvements could be implemented. Based on their findings, they recommended modifications to alleviate operator discomfort, reduce injury risk through better body mechanics, and improve overall performance by streamlining workflows.

Additionally, these changes were thoughtfully designed to enhance worker well-being while increasing production capacity for the company, ensuring a safer and more productive work environment that benefits both employees and the organization as a whole.

Key Skills:

- Ergonomic Analysis & Design

- Human-Centered Research

- Cross-Functional Collaboration

- Data-Driven Decision Making

- Change Management

- Workplace Safety Management

- Vendor/Customer Consulting

- Executive Communication

Role & Responsibilities:

As a member of the project team, I led the ergonomic assessment process, working closely with the operators to understand their pain points and the physical demands of their tasks. Through a series of interviews and observational studies, I gathered valuable insights that highlighted specific challenges faced by the workforce, which included issues such as repetitive strain injuries and improper workstation heights.

I was responsible for conducting comprehensive data analysis using various ergonomic assessment tools, including motion capture technology and workplace surveys, while collaborating with the engineering team to redesign workstation layouts for optimal comfort and efficiency. This involved thoughtful consideration of factors such as seat height, monitor positioning, and tool accessibility to enhance operator well-being.

Furthermore, I presented our findings to the company’s management team, articulating the benefits of ergonomic improvements not only for the employees but also for overall productivity and morale. In addition to analyzing current operations, I helped develop a phased implementation plan designed to introduce ergonomic improvements, carefully ensuring that these changes could be integrated smoothly without disrupting the production line’s workflow or output, and included training sessions to acclimate staff to the new setups.

Challenges:

The project presented several challenges, including the need to balance immediate ergonomic relief for workers with the company’s production goals. The assembly line was already functioning under strict deadlines, and downtime was not an option, which created a sense of urgency and pressure for all team members involved.

Another challenge was addressing the diverse range of rear axles that Android Industries manufactured, each with its own unique ergonomic requirements that varied significantly from one axle design to another. The varying sizes and weights of the axles made it difficult to design one-size-fits-all solutions, requiring a flexible and scalable approach that could adapt to the specific needs of each axle type. This necessitated extensive research and collaboration among engineers, designers, and workers to ensure that the ergonomic solutions not only met safety standards but also enhanced productivity and comfort, leading to improved job satisfaction.

The complexity of these challenges highlighted the importance of an innovative mindset and a commitment to continuous improvement, ultimately fostering a more inclusive workplace for all employees.

Actions Taken:

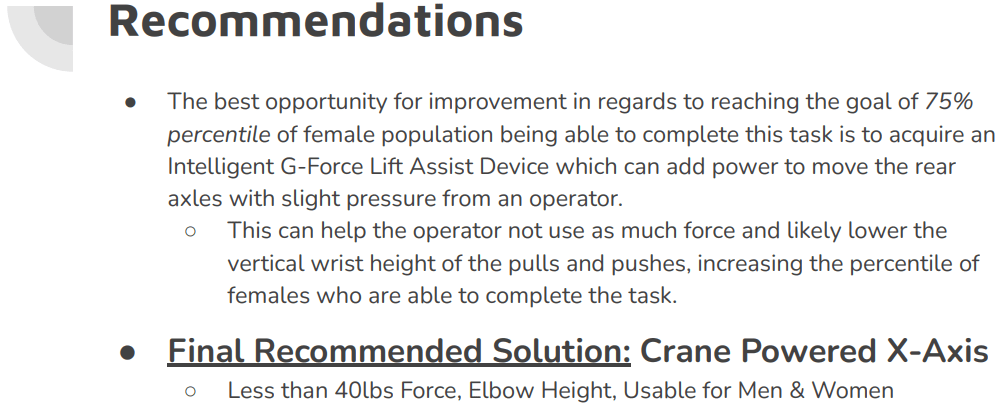

To tackle these challenges, I collaborated with the production and engineering teams to design workstations that could easily be adjusted for different axle sizes and weights, ensuring that the safety and comfort of operators were prioritized. We utilized advanced tools such as the 3DSSPP and the Liberty Mutual Manual Materials Handling Equations to meticulously analyze the forces exerted on operators, which enabled us to identify specific areas that required improvement and modification.

Our team thoroughly researched and recommended new ergonomically designed tools and innovative workstation layouts that allowed for smoother material handling processes and significantly reduced the risk of repetitive strain injuries. To foster a culture of safety and well-being, I also organized regular meetings with the management team to effectively communicate the numerous benefits of implementing these ergonomic changes, emphasizing not only the immediate improvements in operator comfort but also the long-term productivity and safety gains that would ultimately benefit the entire organization.

This collaborative effort epitomized our commitment to creating a supportive work environment that enhances efficiency and employee satisfaction while minimizing injury risks.

Results:

The ergonomic improvements we recommended were successfully implemented in stages, allowing Android Industries to continue production without significant downtime, which was crucial during the transition period. As a result, operator injury risk was reduced by 20%, and production efficiency improved by 15%.

This positive change not only led to fewer workplace accidents but also created a more focused and productive atmosphere on the shop floor. Employee satisfaction surveys indicated a noticeable improvement in comfort and job satisfaction following the ergonomic adjustments, demonstrating that personnel felt valued and heard throughout this process. These adjustments played a vital role in enhancing team morale and motivation.

Furthermore, the implemented changes enabled the company to safely expand its production capacity and adapt to evolving market demands, specifically to handle more diverse rear axle types, positioning production for sustained future growth and competitiveness.

Leave a comment