“Sustainability isn’t just a buzzword, it’s the new baseline. As manufacturers,

we’re no longer judged solely by what we produce, but by how we produce it.”

In the past, manufacturing success was measured by production output, speed, and profitability. While today, those metrics still matter, they’re no longer enough. As climate change accelerates, regulations tighten, and consumer expectations evolve, sustainability has shifted from a corporate ideal to a business imperative. It’s no longer a side initiative; it’s a defining measure of operational excellence that reflects a commitment to future generations and the planet.

As someone who’s worked on the ground floor of high-volume operations and led efforts to reduce waste and improve systems, I’ve seen firsthand how impactful small, intentional changes can be. Implementing basic practices, such as lean manufacturing principles and energy-efficient technologies, can lead to significant reductions in waste and emissions.

Additionally, I’ve witnessed how costly it can be when sustainability is treated as an afterthought. Companies that delay integrating sustainable practices often find themselves not only facing unexpected regulatory fines but also losing market share to more environmentally conscious competitors. Consumers today are more informed and increasingly prefer brands that demonstrate a commitment to sustainability.

Growing Demand for Sustainable Practices

We’re seeing pressure mount from every direction:

Regulators

are enforcing stricter carbon reporting as

well as waste management standards.

Consumers

are voting with their wallets and demanding eco-friendly products and ethical sourcing.

Investors

are looking at ESG metrics as part of

long-term value assessments.

Employees

want to work for companies that align with their values, especially younger generations.

In manufacturing, where processes are complex and resource-intensive, the challenge is clear:

adapt or fall behind. The consequences of inaction aren’t just reputational, they’re operational. Rising energy costs, resource scarcity, and supply chain disruptions will continue to impact bottom lines. Those that fail to evolve won’t just lose relevance, they’ll also lose resilience.

On the flip side, the manufacturers who take this challenge seriously and those who invest in greener technologies, reduce waste, and embrace innovation, will not only survive, but lead the next industrial revolution. Sustainability isn’t just a competitive edge, it’s the cost of entry.

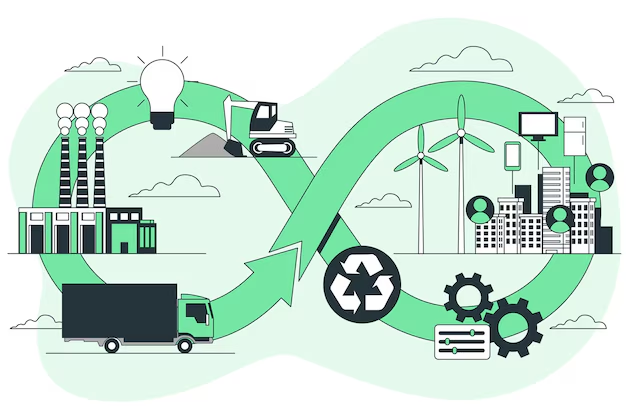

What Sustainability Really Looks Like

Sustainable manufacturing isn’t about perfection; it’s about progress. It starts by embedding sustainable thinking into every layer of operations. That might look like:

- Adopting green technologies: Investing in energy-efficient machines, using automation to optimize energy usage, or shifting to renewable power sources.

- Waste reduction through Lean practices: Re-evaluating every input and output. Can it be reused? Eliminated? Automated? This mindset doesn’t just reduce waste, it often cuts costs.

- Smarter sourcing and logistics: Prioritizing local vendors, consolidating shipments, and using predictive tools to reduce overproduction and transport emissions.

- Closed-loop thinking: Designing systems and products with reusability in mind, from remanufacturing scrap material to reclaiming packaging.

When done right, sustainable practices become embedded into the culture—not just a compliance checklist. It’s not about checking a box or releasing an annual sustainability report with vague goals; it’s about making environmental responsibility a guiding principle.

Take Patagonia, for example. While not a manufacturer in the traditional industrial sense, their approach is a gold standard for embedding sustainability into the company’s DNA. From using recycled materials in their supply chain to offering lifetime repairs to reduce waste, Patagonia doesn’t treat sustainability as a marketing strategy, it’s a core value that drives innovation, customer loyalty, and long-term growth.

Companies with similar values prove that when sustainability is fully integrated, not as a siloed department but as a shared responsibility, real change happens. It drives performance, inspires innovation, and creates a culture where people are proud of what they build and how.

My Experience: Small Changes, Big Results

In my previous role managing tooling operations, I inherited a system where aged material and deadstock were treated as sunk costs. Instead of just discarding them, I launched a reallocation initiative and strived to find opportunities to repurpose or credit those assets. That single change recovered over $30K and opened the door for broader sustainability conversations across various departments and customers.

It proved to me what sustainability advocates have said for years: going green doesn’t mean going broke. It means getting creative. It means asking better questions. And it means thinking beyond the moment, toward the long-term value we can create.

Sustainability = Strategy

It’s not actually sustainability that’s expensive, it’s the inefficient systems and reactive planning that cost us the most. When operations rely on outdated processes, waste accumulates, energy is misused, and resources are poorly allocated. That leads to higher overhead, regulatory penalties, and missed opportunities. In contrast, sustainable manufacturing isn’t just about environmental responsibility, it’s a strategic advantage.

Here’s what companies gain when they take sustainability seriously:

- Reduces Long-Term Operating Costs

- Improves Compliance and Reduces Regulatory Risks

- Enhances Brand Trust and Employee Loyalty

- Opens Doors to Government Incentives and ESG-Focused Funding

That’s why forward-thinking companies aren’t treating sustainability as a marketing angle, they’re treating it as a core business strategy. It’s not about looking good in a press release; it’s about building systems that are smarter, stronger, and more resilient in the face of change.

The return on sustainability isn’t just environmental, it’s operational, reputational, and financial. And those who embrace it now will lead the industries of tomorrow.

Building a Sustainable Culture Starts With Us

You don’t need a sustainability title, a green lab coat, or a corner office to make a difference. In fact, you don’t even need to be the loudest person in the room to have a significant impact. Each day in industries like manufacturing, procurement, planning, and operations, your expertise and decisions shape processes that influence environmental outcomes.

By embracing sustainability within your role, no matter how seemingly minor, you possess the power to drive change. This can be achieved through small yet impactful actions, such as proposing energy-efficient practices, advocating for sustainable sourcing, or setting measurable goals for waste reduction. Your insights and initiatives can spark a culture of sustainability that inspires others, proving that every individual truly has the potential to create a ripple effect.

Here’s how you can start making an impact right where you are:

- Be Curious, Not Complacent

- Treat Waste Like a Red Flag, not Background Noise

- Choose your Partners Like You Choose Your Playlists

- Challenge the Classic “We’ve Always Done it This Way”

Sustainability isn’t a job title—it’s a mindset. And when more of us start thinking this way, even the smallest changes can ripple into something bigger.

Final Thought: Our Responsibility to the Future

Sustainability in manufacturing is essential and long overdue. The choices we make today extend beyond just production goals; they affect our operations, the communities we live in, and the health of our planet. As manufacturers, we have a duty to deliver products in ways that save resources, reduce harm, and foster long-term sustainability.

This responsibility is not just for executives or environmental experts; it involves everyone. From buying materials to planning and logistics, each role is vital in creating a more sustainable future. We need to change our mindset: moving from reacting to problems to preventing them, from sticking to old ways to finding better solutions, and from focusing on short-term gains to committing to long-term results.

The companies that will succeed in the future of manufacturing aren’t just the fastest or cheapest; they are the ones bold enough to incorporate sustainability into every decision. They focus on building more than just products—they aim to build trust, resilient teams, and a lasting positive impact. Ultimately, manufacturing is not only about making things; it’s about the legacy we create.

Including sustainability in all areas of manufacturing isn’t just a trend; it’s a necessary change in how businesses function. By adopting this approach, manufacturers can prepare for success in a world where being environmentally responsible is linked to innovation and resilience.

Leave a comment